Üretim

ÖRGÜ

Gülçek Tekstil, 117 yuvarlak örgü makinesiyle günlük 40 ton kapasiteye sahiptir. Düz örme grubu haricinde Raşel dokuma'da farklı kalitelerde hizmet vermektedir. Makina parkuruyla Süprem, Süprem Elastan, Pike, Üç İplik, İki İplik, Polar, Havlu, İnterlok, Ribana, Raşel ve türevleri gibi farklı örme kumaş türleriyle sektöründe liderdir. Üretimin tamamı kalite kontrolden geçtikten sonra ilave işlemleri yapılmak üzere boya ve baskı tesislerine gönderilir.

BOYA

HT - Jet makineleri, 25 kg'den 1.400 kg'ye kadar değişen kazan kapasiteleri ile her türlü pamuk, viskon, modal, tencel, polyester, bambu ve elastan karışımlı kumaşlar tek boya-çift boya kimyasal otomasyon boyama sistemleri ile boyanmaktadır. Boya ve terbiye işlemlerinde kullanılan makina teknolojilerini yakından takip ederek makine parkurumuzu günümüz teknolojilerine göre yenilemekteyiz. Günlük üretim kapasitemiz 35 ton'dur.

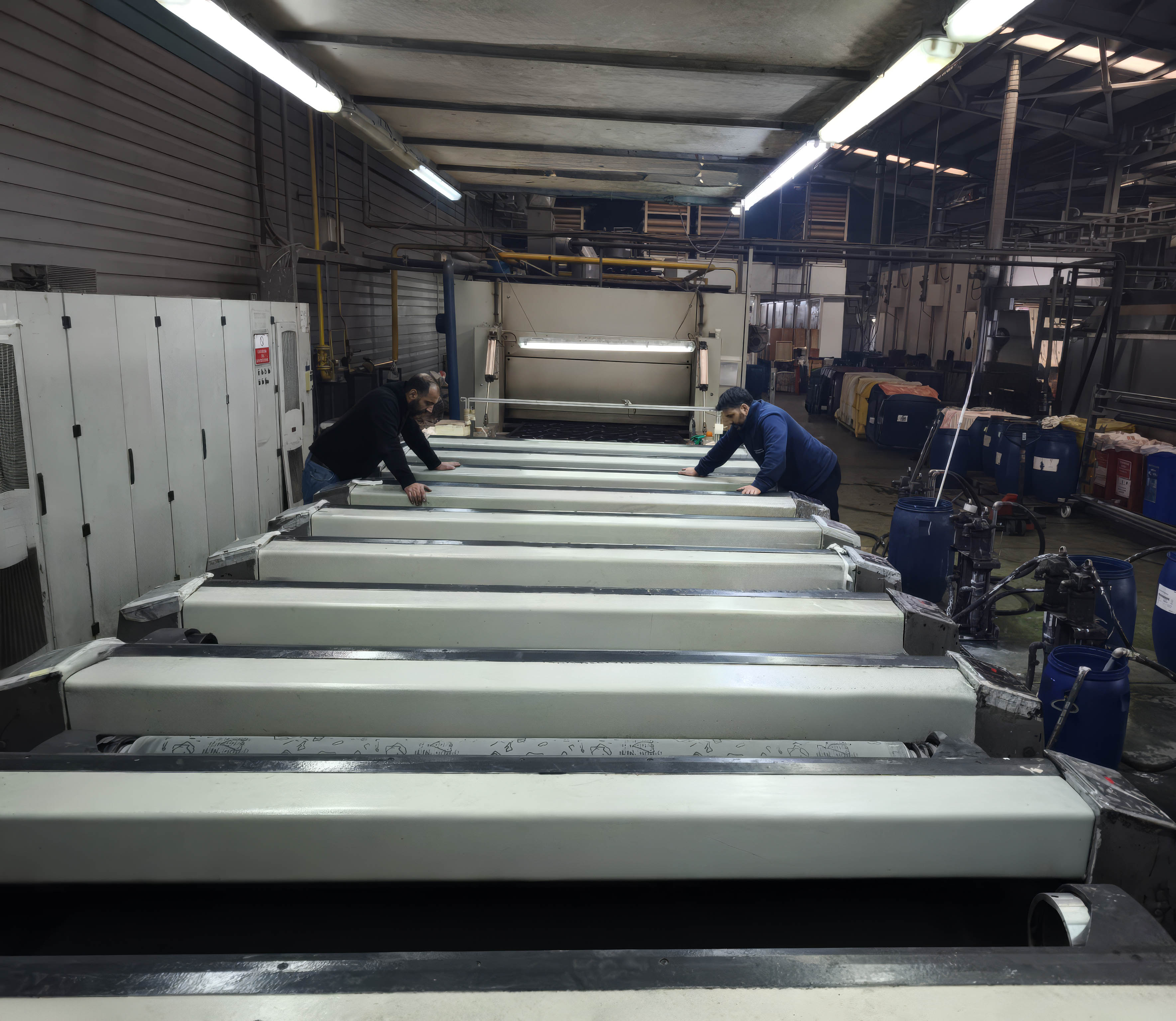

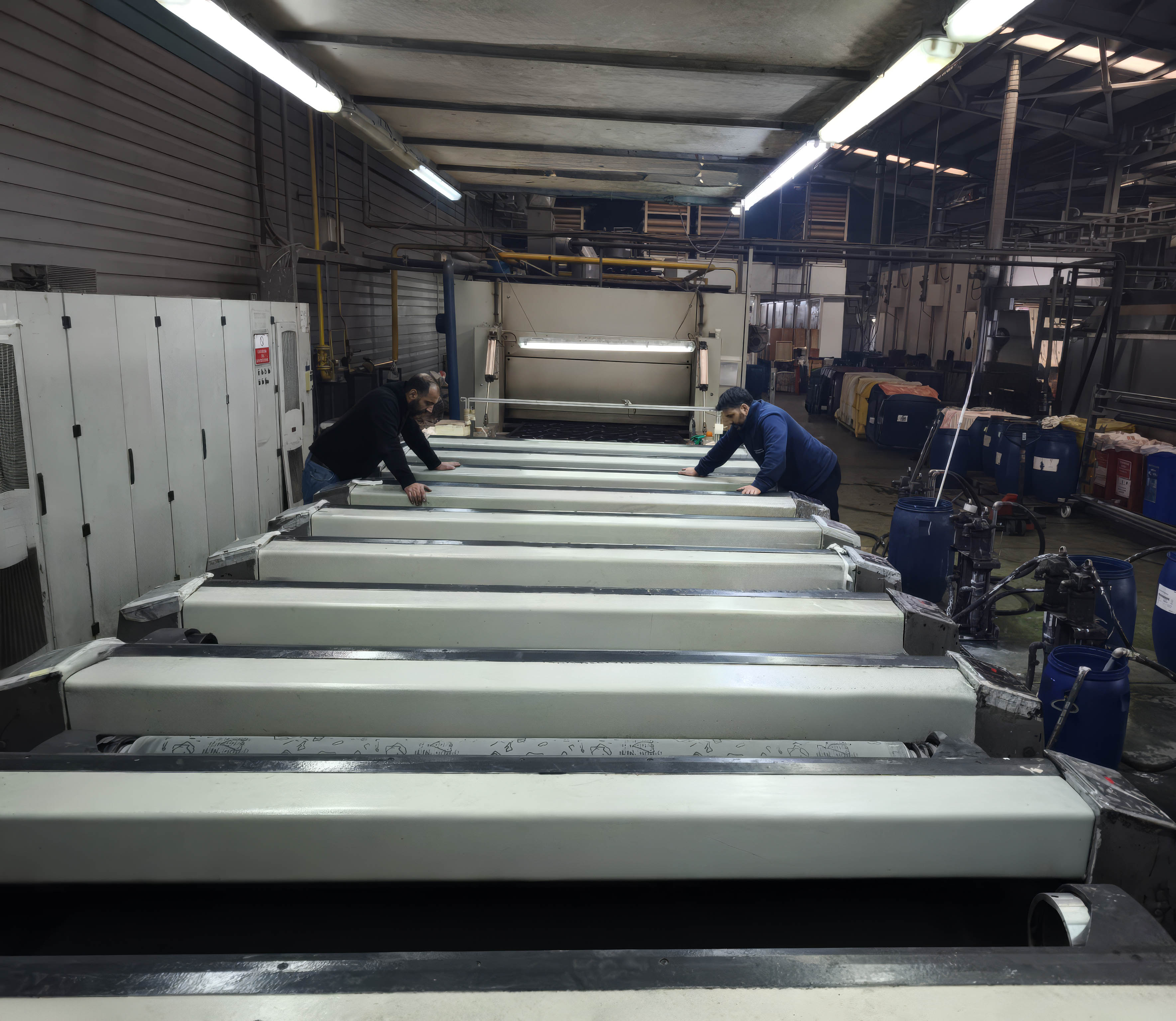

BASKI - ROTASYON BASKI

Gülçek Tekstil, 2 adet rotasyon baskı makinesi, 1 adet buharlama makinesi ve 1 adet kontinü yıkama makinesi ile günlük 10 ton kapasiteye sahiptir. Üretim sürecimizde renk tutarlılığı, desen netliği ve tekrarlanabilir kalite odaklı çalışıyor; farklı kumaş türlerine uygun reçete ve proseslerle baskıyı standardize ediyoruz. Baskı çeşitlerimiz: Reaktif Baskı, Pigment Baskı, Pigment Aşındırma ve Dispers (Disperse) Baskı.

APRE

Özel donanımlı santex kurutma, ram, sanfor, kontinu yıkama, fırça, şardon, traş, gaze, tumbler işlemleriyle boyalı ve baskılı kumaşlar istenilen talep doğrultusunda terbiye edilerek bitim işlemleri yapılmaktadır. Müşteri isteğine göre özel apreler ( ipeksi apre, quick dry, ter emici, moistoure management, wicking, su itici, kir itici, anti-bakteriyel, antidoor, UV apre, stay new apre) yapılmaktadır.

KALİTE KONTROL

4 adet otomatik kontrol ve paketleme makinesine sahip kalite kontrol birimimizde üretimimizin her partisi %100 kontrole tabi tutulmaktadır. Fizik Laboratuvarında; Yıkama Haslığı, Su Haslığı, Asidik-Alkali Ter Haslığı, Sürtme Haslığı, Tükürük ( Saliva ) Haslığı, Işık Haslığı, Asidik-Alkali Terli Işık Haslığı Testi, Oksidatif Ağartıcıların Etkisi Testi, Sararma ( Fenolik ) Testi, PH Testi, ICI Piling Testi, Martindale Piling Testi, Patlama Mukavemeti Testi, Baskı Dayanımı Testi, Boyutsal Değişim Testi, Dönme Testi, Gramaj Testi yapılmaktadır. Kalite Bilgilerini içeren kalite kontrol raporu ve partinin tüm fiziksel kalite değerleri sisteme girilmektedir. Bu föyler müşteriye sunulmaktadır.